homepage /

conveyor /

accumulation tables

BI-DIRECTIONAL AND RECIRCULATING ACCUMULATION TABLES

Solaut realizes accumulation tables to be used in intermediate positions of the conveyor systems.

The product accumulation tables are divided into two types:

Download the pdf catalog of accumulation tables

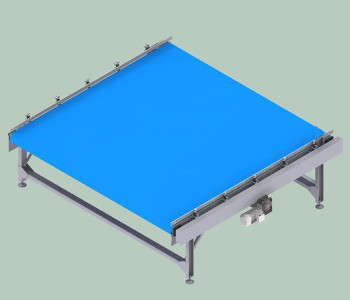

RECIRCULATION ACCUMULATION TABLE

The horizontal recirculation accumulation tables are typically inserted inside a conveyor section to allow

both the accumulation and the subdivision of the product on several exit lines.

The accumulable products are circular section bottles or similar products.

The figure shows an example of an accumulation table: a pair of motors perform product recirculation.

The structure of the conveyor can be be made of painted, galvanized or stainless steel.

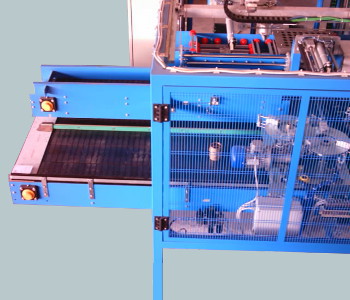

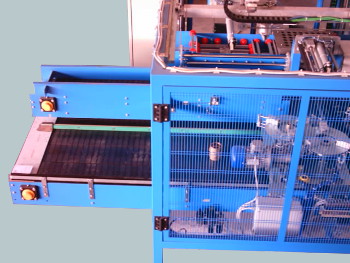

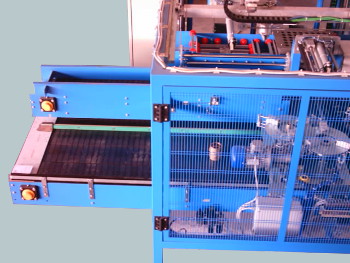

The figure on the side represents a special accumulation table, made for a mechanical industry.

The accumulated products are bearing rings.

In this application the entry of the products does not consist of a conveyor.

The products are introduced by a gantry robot that picks up the rings from a box.

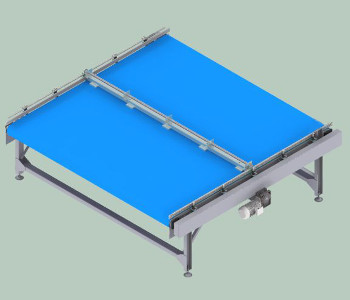

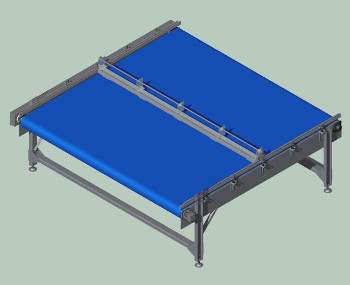

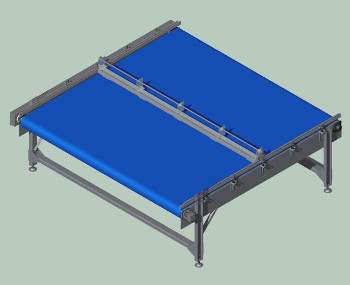

BI-DIRECTIONAL ACCUMULATION TABLE

The horizontal accumulation tables are modular or table-top conveyors, with a large width

(up to 3 meters) with lengths up to 6 meters.

This accumulator is used as a buffer to be inserted between plant machines.

The horizontal accumulation tables during loading move the modular belt in one direction;

the direction of movement is opposite when unloading.

To achieve the double direction of movement, chain conveyor control is made with two transmission shafts

at the two ends of the table.

For the transmission of the conveyor chain we can propose two solutions::

- double motorization with friction clutches

- central motorization with pair of high backlash couplings

In double motorization models each shaft is driven by a dedicated gearmotor; the movement is controlled

by a clutch which connects the gearmotor to the shaft with the conveyor chain drive sprockets.

In the models with central drive we have a single gearmotor mounted in the middle of one of the two sides.

The motion is transmitted to the two shafts by means of a transmission chain that meshes with two pinions

that control the movement of the two drive shafts of the conveyor chain.

The sprockets are not rigidly mounted on the shaft but transmit the drive torque through a joint with 120°

of angular backlash.

Thanks to the high backlash the idle shaft is pulled by the conveyor chain and not by the transmission chain.

Essential features:

- Plastic modular chain or steel table top chain.

- Standard versions with Bonfiglioli worm gearmotors.

- The structure of the conveyor can be be made of painted, galvanized or stainless steel.

- Complete supply of electrical panel and control software on Siemens or Omron PLCs.

Bi-directional accumulation tables are divided into two families according to whether the products

are accumulated in an bulk way or sorted in rows.

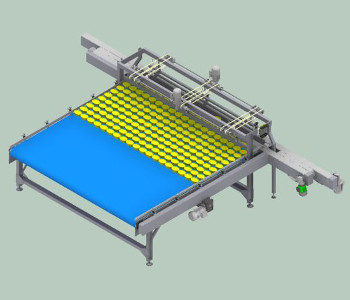

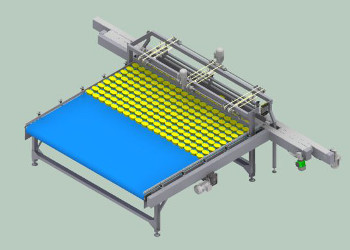

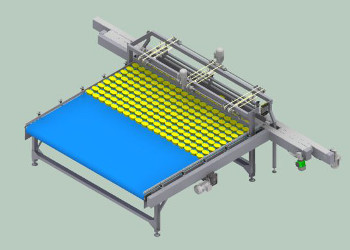

ORDERLY ACCUMULATION

The orderly accumulation is required for those products with a parallelepiped or oval shape that are

extracted in rows ordered by the conveyor and with the same order must be reinserted into the conveyor.

The displacement of the ordered rows is carried out by means of a pair of mobile diverters controlled

by servo drives that are inserted on the conveyor of the line and once the row is created,

they move it on the table.

The displacements of the table are steps of a length equal to the width of the row of products,

plus the distance of the rows.

The position of the conveyor chain is acquired by an encoder mounted on the drive shaft.

The re-entry of the products accumulated on the conveyor line can occur for whole rows

if it is possible to create sufficient space on the conveyor to insert a whole row.

If this last condition is not feasible and therefore, the products must be put back into conveyor line

in small groups, a dosing conveyor must be inserted.

The dosing conveyor is parallel to the line conveyor and receives the products through a diverter.

The rows are created on the dosing conveyor before being moved on the table.

The on-line re-entry of the accumulated products takes place first by moving a row from the table

to the dosing conveyor.

The products are put back on the line, stopping the flow on the line conveyor through a stop and

puting in one or more products with dosing conveyor into the line conveyor.

All system parameters can be entered or modified on the operator panel of the electrical panel

of the accumulation table.

BULK ACCUMULATION

A typical application is the bottling sector, where the products are mainly circular.

At the base table is added a transverse containment guide resting on the conveyor chain.

The transverse containment guide has a chain balancing shaft that keeps the guide perpendicular

to the direction of movement of the conveyor chain.

The transverse containment guide controls two switches placed at the ends of the table in the positions of full and empty table.