homepage /

robot / Cartesian CC

CARTESIAN AXIS COLUMN ROBOTS CC SERIES

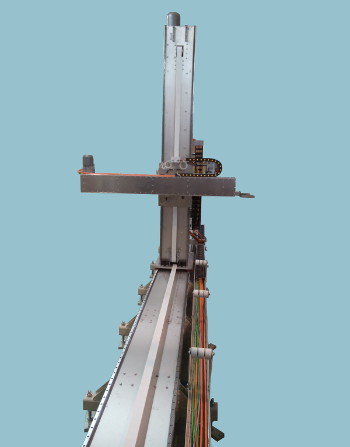

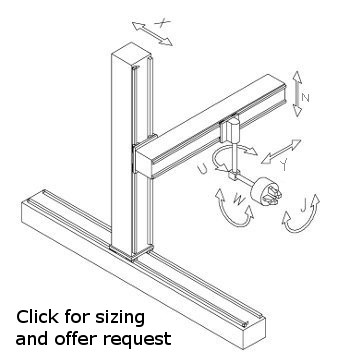

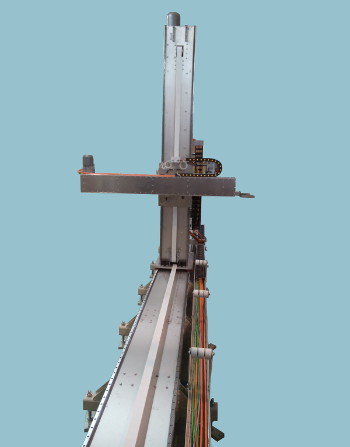

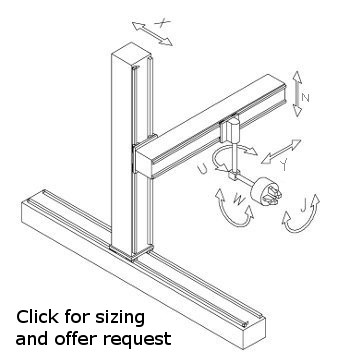

The CC Cartesian axis manipulators are shown in the figure to the left.

The manipulators can be supplied with 3 Cartesian axes and any combination of the rotation axes.

The U, W, and J rotations can be controlled by servomotors or, if there are only two positions,

it is possible to use pneumatic actuators.

The axle transmissions are made with epicycloidal reduction gears.

The servomotors are Panasonoc or Omron for manipulators with light and medium sizes.

For the medium and heavy sizes of manipulators the servomotors and servo drives are Kollmorghen.

Cartesian axes can have independent positioning or can be interpolated (linearly, circularly or with particular curves).

Complex interpolation forms are obtained using axes control cards.

The Cartesian axis manipulators of the CC series are available with timing belt or rack and pinion transmissions.

The axle versions with timing belt drives can have the X-axis motor "on the ground" as shown in the figure alongside,

or with the motor on board the carrier moving along the X axis, as in the figure at the top of the page.

The position feedback of the axes is realized with the resolver or encoder of the motor.

For applications where high precision in positioning repetition is required,

the position feedback of the axes can be realized with optical lines.

The CS series Cartesian axis robots can be supplied in 3 sizes:

- Light size with a payload up to 10 kg

- Medium size with a payload up to 50 kg

- Heavy size with a payload up to 150 kg

All the models described above can be supplied in an economic version for applications with limited performance.

Sanyo stepper motors with RTA drives can be installed in light-weight machines.

In the other versions, inverters and three-phase asynchronous motors with LENZE encoders can be mounted.

Beside it is depicted a light series Cartesian 4-axis machine used for a machine tool tending.

The control of the system was carried out with a CNC.

Cartesian axes robots can be supplied in the following configurations:

- Basic supply of axes only, no motors, no sensors and no electrical system

- Supply as in point 1 plus support frame

- Supply as in point 1 plus electric panel with PLC (Siemens, Omron or Mitsubishi) or CNC, HMI touch screen 7" color, motors and drives, sensors

- Supply as in point 3 more control and command software

ECONOMIC VERSION

An economic version is available for all manipulator models.

Lightweight manipulators can be supplied with Sanyo stepper motors and RTA drives.

Medium and heavy size manipulators can be supplied with asynchronous motors and inverters

(a solution to be used for lower performance applications).

The manipulators with inverters mount Lenze series 8400 HighLine motors and inverters.

Thanks to the Motion Control Kernel of the inverter, an asynchronous motor servo control can be implemented.

The positioning commands are sent to the inverter via the CAN OPEN bus (on board) or with an additional module:

Profibus Dp, Profinet, EtherCAT, EtherNet / Ip.

Download the pdf catalog of Cartesian axis robots