homepage /

robot / Cartesian CC

CARTESIAN ROBOTS PICK AND PLACE CD SERIES FROM 2 TO 6 AXIS

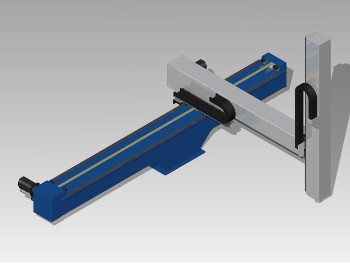

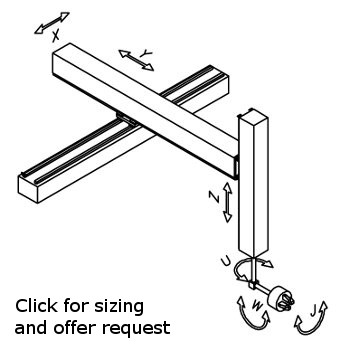

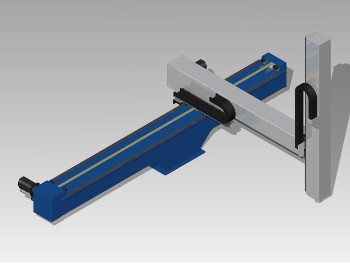

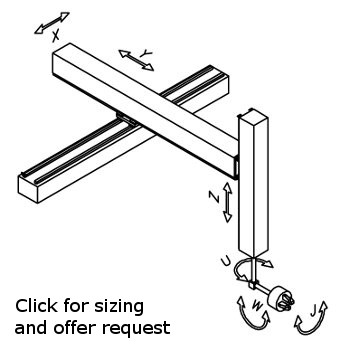

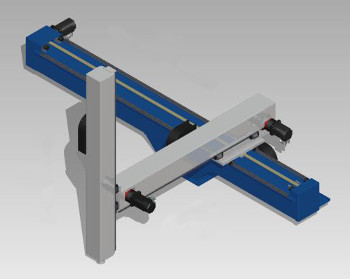

This type of robot has a fixed axis on the ground (X axis) on which a second axis (Y axis) runs

both longitudinally and transversely (two degrees of freedom).

The third Cartesian axis is the Z axis that runs transversely to the Y axis at one end of the latter.

Cartesian robots CD series can be supplied in 3 sizes:

- light size with payload at wrist up to 10 kg

- mid-size with payload at wrist up to 50 Kg

- heavy size with payload at wrist up to 100 Kg

Gli assi del pick and place possono avere posizionamento indipendente oppure movimenti interpolati (linearmente, circolarmente o con curve particolari).

Le forme di interpolazione complesse si ottengono con l'utilizzo di schede assi.

Il robot cartesiano pick and place CD č schematizzato nella figura a fianco.

Il pick and place č disponibile con i 3 assi cartesiani e con qualsiasi combinazione degli assi rotanti.

Le rotazioni U, W, e J sono comandate da servomotori oppure, qualora si abbiano solo due posizioni,

č possibile montare degli attuatori pneumatici.

Per corse dell'asse Z del pick and place particolarmente lunghe, l'asse Z puō essere telescopico per ridurre gli ingombri verticali.

Le trasmissioni sono realizzate con riduttori epicicloidali a gioco ridotto. I motori sono Panasonic oppure Danaher Motion.

I pick and place della serie CD sono fornibili con trasmissioni a cinghia o con cremagliera e pignone.

Le versioni con trasmissioni a cinghia possono avere il motore dell'asse X "a terra" oppure

con il motore a bordo del carrello traslante lungo l'asse X.

La retroazione di posizione degli assi del pick and place č realizzata con il resolver od encoder del motore.

Per applicazioni in cui č richiesta un'elevata precisione nella ripetitivitā del posizionamento, la retroazione di posizione

degli assi lineari del pick and place puō essere realizzata con righe ottiche.

Sono disponibili soluzioni economiche dei pick and place serie CD.

I pick and place cartesiani sono equipaggiati anche con motori asincroni ed inverter per le taglie media e pesante, in applicazioni con prestazioni e precisioni di posizionamento ridotte.

Gli inverter utilizzati sono i Lenze 8400 serie High Line che integrano un software di servo posizionamento per motori asincroni.

La versioni leggere possono montare in alternativa ai servomotori, motori passo passo Sanyo ed azionamenti RTA.

I pick and place cartesiani serie CD sono fornibili nelle seguenti configurazioni:

- Fornitura base dei soli assi, senza motori, senza sensori e senza impianto elettrico

- Fornitura come al punto 1 pių telaio di sostegno

- Fornitura come al punto 1 pių quadro elettrico con PLC (Siemens od Omron) o CNC, pannello operatore touch screen 7" colore, motori, azionamenti e sensori

- Fornitura come al punto 3 pių software di controllo e comando

INJECTION MOLDING MACHINE ROBOT

CD series pick and place robots sizes according to the injection molding machine:

- Light size with payload up to 10 Kg for the handling of molded parts on presses of small and medium tonnage (from 40 to 500 ton)

- Mid-size with payload up to 50 Kg for the handling of molded parts on presses of medium tonnage (from 500 to 1200 ton)

- Heavy size with payload up to 100 Kg for the handling of molded parts on presses of medium-heavy tonnage (from 1200 to 2500 ton)

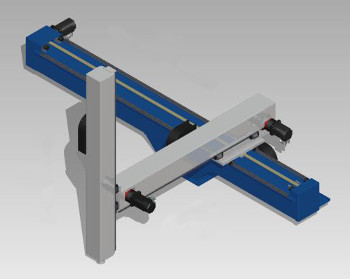

The three horizontal cross-axis Cartesian robot CD series is the "arm" of the automation system of the injection molding machine.

The Cartesian robots CD series are mainly designed to satisfy the special requirements of injection molding.

All these robots are equipped with a vertical axis Z, that allows them to reach the area between the two half-molds, of an X axis,

represented by the horizontal cross member, which generally extends above the mold up to protrude from the perimeter of the machine,

and a Y axis, which moves the arm vertically in line with the machine, so as to extract the products from the mold and move them

outside the molding.

If it simply needs a robot that removes the products from the press in order to obtain quick and repeatable cycles, a three-axis robot is more than enough.

It is only when it begins to demand more to the robot, for example, additional functions for manipulation inside the mold or outside of the press,

that you begin to consider the purchase of robots with four, five or six axes.

The addition of a wrist Servocontrolled, gives to Cartesian robots two or three additional axes and features very similar to those of the models to six articulated arm axes.

At the opposite end of the spectrum, the articulated six-axis robots are equipped with an arm similar to a human arm.

It is able to catch an object in almost any angle and at any point within its range. Some of these movements have been integrated, with pneumatic drive,

even in the three-axis robot wrist (axes U, J, W tires).

These movements allow the wrist rotation continuously from 0 ° to 90 ° or from 0 ° to 180 ° without any intermediate stop.

According to the number of additional automation solutions installed in the molding cell

- For example power devices of inserts, measuring, removing burrs, welding or decoration -,

However, the simple addition of the rotations of the wrist of a three-axis robot can give rise to an automated system rather complex.

Servo-robot with five or six axis

These robots offer many of handling functions of the manufacture of six-axis robots with an articulated arm,

but in an intuitive configuration for anyone who has used a three-axle model.

The axes X, Y and Z are the same: it is the servo-operated wrist at the end of the vertical arm that makes the difference.

The U J and W movements are available, but instead of carrying out complete oscillations from 0 ° to 90 ° or from 0 ° to 180 °,

the pulse can be stopped at any point of the arc; all these movements, in addition, can be executed simultaneously.

In fact, the robot is able to use all axes simultaneously and in an absolutely controlled way. The secret is in servo motors.

In pneumatically operated models, the valve opens and the air pressure actuates the pulse;

the pulse continues to move until it reaches a stop element (limit switch), which closes the valve and interrupts the power supply.

A servo motor, instead, is equipped with a position encoder, able to identify the position of the transmission with precision and at any time.

The system control unit, at this point, can integrate the position signals sent by the servomotors of all five axes,

identifying with accuracy, at any time, at which point in the space the clamp and the artefact are.

This allows the robot to perform extremely complicated movements with great precision and repeat them perfectly.

The advantages of the robots with five, six axis:

If you have aproduct with a complex geometry which can not be extracted from the mold with a linear movement,

or if the light between the two mold halves or between the columns is limited, it may be necessary to rotate the product for lifting it out of the press.

The Servocontrolled wrist is able to perform this type of multi-axis movements, exactly like a hand and a human wrist, but with a superior speed and precision.

Once extracted the article from the mold, you may need to subject it to secondary processing,

as for example apply glue and assemble it to other components, or remove the burrs on the edges with a flame.

The five-axis robot is able, without releasing the product, to move it with precision close to the flame or to the gluing head.

The level of efficiency guaranteed by this solution is greater than that which could offer a human operator,

engaged to perform the same operations or to block the product in a fixing system so that other automation devices carry out the processing secondary requests.

The modern Cartesian robots with five axes offer a lot of advantages, such as a high input speed, which ensures reduced cycle times,

and all the flexibility of a robot articulated arm both inside and outside of the mold.

The five-axis robots are therefore able to perform many of the complex operations of manipulation of products generally performed by the articulated models .

Download the pdf catalog of Cartesian pick and place