homepage /

sheet loader-feeder /

gantry loader

PORTABLE SHEET FEEDERS ACRAB

Solaut produces portable automatic sheet feeders for loading / unloading, loading and unloading of sheets and plates.

The acrab table feeders are used in the automation of product handling in printers and cutting plotters.

The characteristic common to all the models is the presence of a lifting table

that brings the product to be loaded to the grip level by the suction cups.

The portable table feeder models we produce are:

Download the pdf sheet feeders catalog

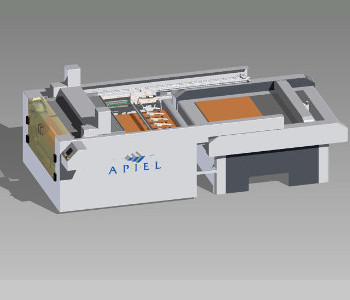

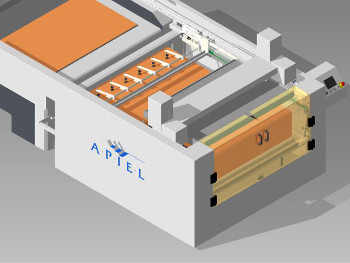

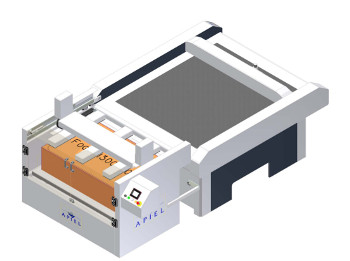

SHEET FEEDER ACRAB-T

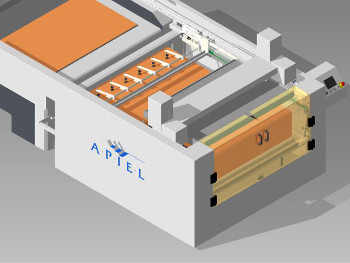

The ACRAB-T sheet feeder is a machine designed for loading and unloading cutting plotters.

The peculiar characteristics of the machine are 2:

- high speed

- possibility to remove machined sheets with full cut

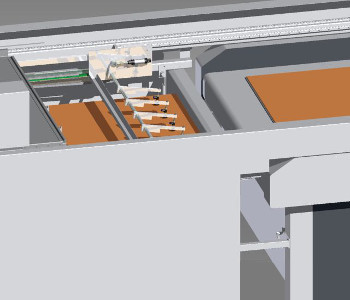

High speed was achieved with a pair of gripping elements: a suction plate removes

the processed sheet from the plotter table.

As soon as the sheet is lifted from the plane of the plotter, a second suction cup group positions

the sheet to be processed.

Thanks to the independence of the two loading and unloading groups, the time lost for sheet replacement is less than 2sec.

The use of a suction plate for removing the cut sheet allows both the finished product and the waste to be removed.

This feature allows its application also in paper and cardboard converting .

The figures to the side show that the packs of sheets to be cut are stacked inside the machine (orange stack on the left).

The cut sheets are deposited in the stack on the right.

Both stacks rest on elevated plates which, thanks to a series of sensors,

keep the upper edge of the stacks at a constant height.

Thanks to the constant grip level, it is possible to install systems to avoid multiple picks

(air blades, brushes or slats).

It is possible to insert ultrasonic sensors to check that 2 sheets are not taken at a time.

The sheet feeders of the ACRAB-T series are sized to mate with a very precise plotter model.

Thanks to the frame with wheels, the ACRAB-T automatic feeder can be easily moved,

allowing the use of the plotter in the manual way.

The feeder can be used on different plotters: the machine has integrated the electrical panel.

Thanks to two fixing arms it is possible to fix the feeder to the plotter.

The ACRAB-T feeders are available in the following sizes:

- Front 800 depth 400

- Front 800 depth 800

- Front 1350 depth 800

- Front 1350 depth 1200

For operation, the feeder requires:

- 230V 1Kw power supply

- 5bar pneumatic supply

- Connection to a blower to feed the vacuum plate

- Plotter predisposition to be able to interface with the feeder

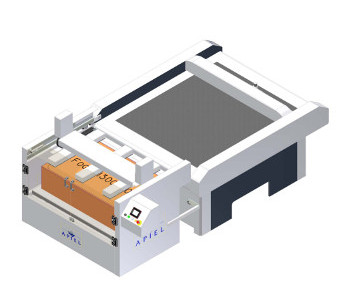

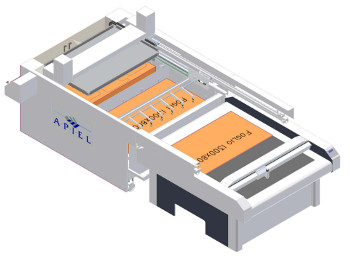

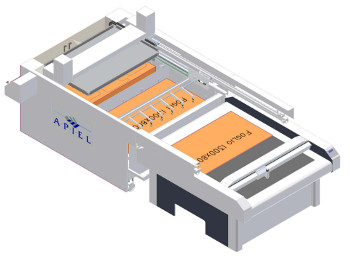

SHEET FEEDER ACRAB-CT

The sheet feeder in the CT version is used for loading cutting plotter or in general for positioning sheets.

The feeder offers the possibility to load from 1 to 5 sheets simultaneously.

The various models are made in relation to the front and depth:

- Front: 800 depth: 400/800

- Front: 1350 depth: 800/1200

- Front: 1800 depth: 1000/1600

- Front: 2270 depth: 1200/2000

The machine shown in the figure works to automate the loading of sheets and panels on large flat bed or

comveyor cutting plotter.

The feeder is equipped with wheels that make it easily transportable if its use is not necessary.

It is possible to use the feeder on several machines (plotters of different types and sizes)

thanks to the easy interconnection with the machine.

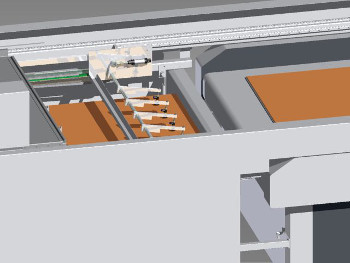

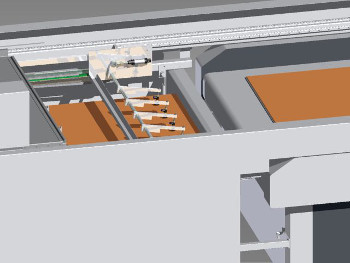

SHEET FEEDER ACRAB-ST

The sheet feeder in the ST version is used for the unloading of cutting plotters, flat bed printers

or in general for automatic sheet removal and stacking.

The various models are made in relation to the front and depth:

- Front: 800 depth': 400/800

- Front: 1350 depth': 800/1200

- Front: 1800 depth': 1000

The machine in the figure besite has been designed for the automatic unloading of a Zund plotter.

The machine is equipped with vacuum plates for removing cut sheets.

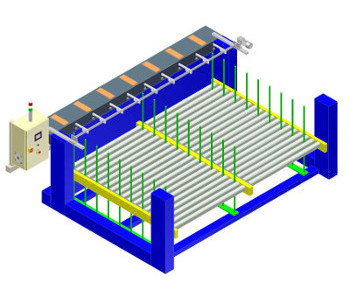

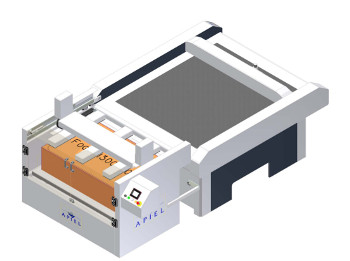

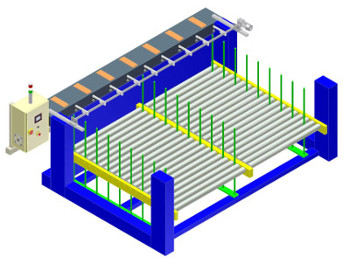

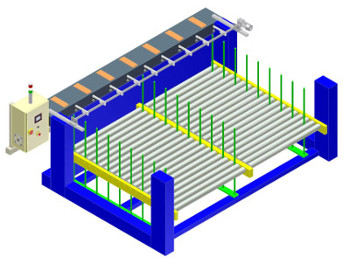

SHEET FEEDER ACRAB-FB

The feeder offers the possibility to load from 1 to 5 sheets simultaneously on large format ink jet

flat bed printers such as DURST RHO P10 / 250.

This model of feeder loses the portability of previous models.

The feeder is made in two models, based on the width:

The feeder is able to load sheets, panels and plates on the Durst Rho Pro 250 large format printer.

The feeder is made up of a sheet magazine with an elevating roller surface able

to keep the first sheet in a fixed position.

The support roller of the sheets will be provided with a series of guides for containing one or more sheets (max 5)

with variable dimensions at will.

The 3 internal guides have a transversal position adjustable by means of handwheels and height indicators.

The second component of the feeder is the sheets gripping device: a series of suction cups with adjustable positions,

hook the sheet / sheets and lift it by turning the flap.

A series of nozzles blow air to facilitate the detachment of sheets stuck to the first.

The sheets gripping device advances to bring the sheet onto the drive unit.

The third component of the feeder is the drive unit: made up of a series of perforated belts which,

fed by a series of vacuum generators, hook the sheet and feed it inside the printer.